What is the difference between LDPE and HDPE Irrigation pipes

LDPE HDPE Difference is crucial when designing a good system. You can either save a lot of money initially and waste a lot later when your irrigation system starts popping.

The irrigation pipes ensure that water is supplied to the plants. The most common used pipes are the LDPE types. They range between 1 and 8 mm spaghetti pipes used in bag cultures to 12 mm – 35 mm used for supplying the water from the various tanks to the plants. The minimum size used to transport water is 20 mm LDPE pipe. Header lines are usually 40 mm – 50 mm HDPE.

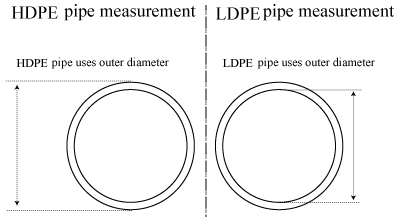

In closed hydroponic systems the effluent line is usually a 110 mm PVC drain pipe. The effluent pipes must be able to handle large volumes of effluent water running back the collection or catch-up tanks. The do not need to cope with high pressures such as the header lines. NOTE: when measuring PE pipes the outside diameter is used with HDPE (High Density) and the inside diameter is used for LDPE (Low Density). LDPE pipes are suitable for pressures below 3 Bar while HDPE is used for pressures from 3 Bar upwards.

PE pipes or polyethylene pipes come in two variants, low pressure (LDPE) and high pressure (HDPE) pipes. LDPE operates between 1-3 bar and HDPE between 3-12 bar. When ordering pipes make sure you take the correct measurements since both types are measured differently.