Cooling a greenhouse with fogging nozzles

Many growers have tried reducing temperatures (cooling) with fogging nozzles. The concept of spraying the air with microscopic water droplets which absorb the heat in the air sound right. However, fogging does not just decrease the temperature, it increases the humidity as well.

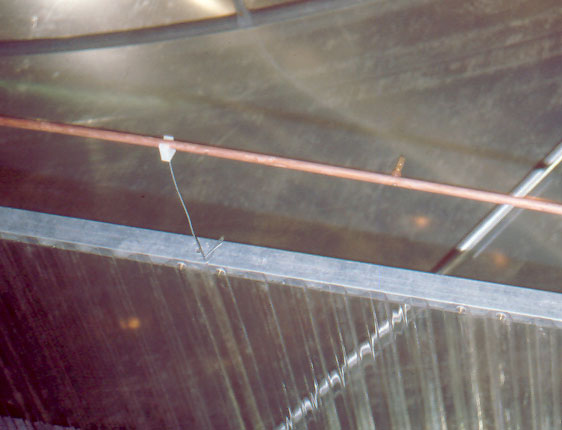

A fogging system cannot operate efficiently if it does not have a very high pressure of between 100 and 300 bar. Any attempt in designing a system with normal PVC irrigation pipes and 360 ° irrigation nozzles will cause more damage to the crop than anything else. Too low pressure will result in large droplets forming which will reach the plants, moisten the leaves and increase the risk of diseases. In order for a droplet to stay suspended in the air and not reach the plants it should be smaller than 10 microns. At this size the droplet will stay suspended and through evaporation it will quickly reduce in size and evaporate completely. Fogging systems are very expensive. Depending on system design, the water pipes are usually made from copper with special copper nozzles. These nozzles release water between 1.12 – 2.27 L/h. Plastic irrigation sprinklers release water at a rate of 1-2 L/min, a vast difference.

The advantage of misting or fogging is that the transpiration rate of the plants is reduced. This is especially important for various floricultural crops and some vegetable crops such as lettuce which suffer from tip burn during high temperatures and low humidity. Fogging systems are highly specialised and a specialist should be consulted before designing one’s own system. The advantage of fogging is that wet bulb temperatures can be reached whereas pad and fan systems the temperature is 1-2 °C higher than wet bulb temperatures.

Fogging nozzles are highly specialised systems that work on very high pressure. Not effective in climates with high humidity. Water tends to form precipitates can clog the nozzles. An increase in diseases can also be a problem.